Colourant Reduction Concept

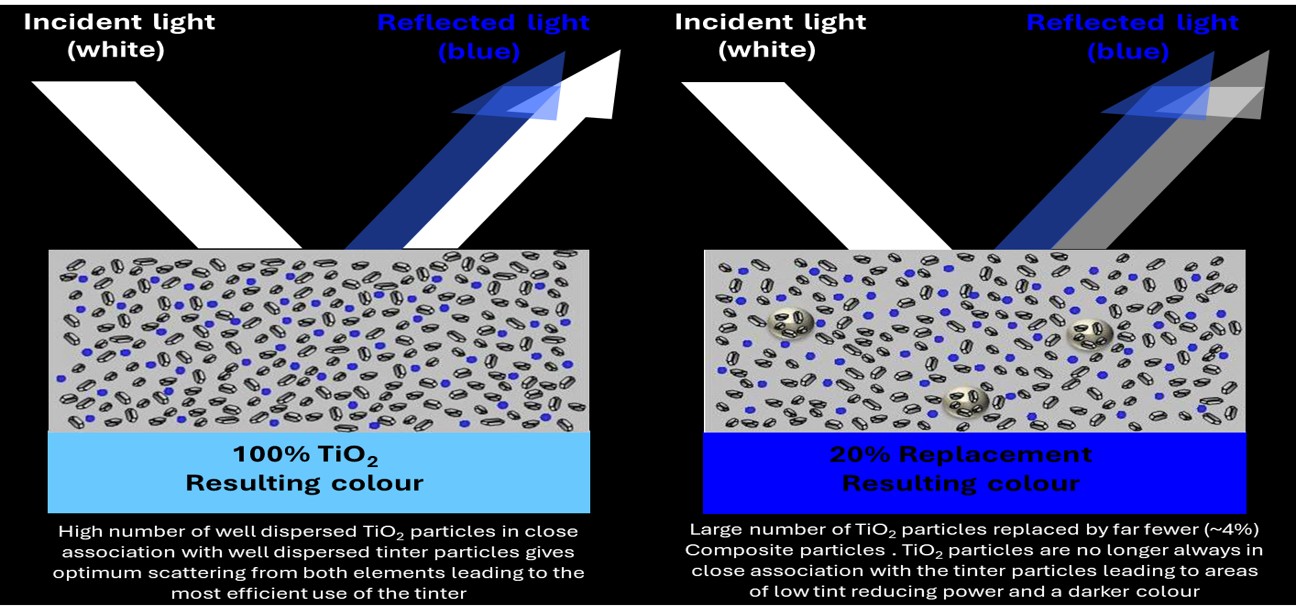

While FP-Opacity Pigments™ are primarily designed to partially replace TiO2 pigment, they also have a lower tint reducing power than TiO2. This unique property allows for a match in opacity but, at levels above 6% replacement, delivers a darker colour. This effect can be explained by the overall reduction in scattering centres where a weight for weight replacement of TiO2 with FP-Opacity Pigments™ results in only approximately 4% of the particles being added back (see diagram opposite).

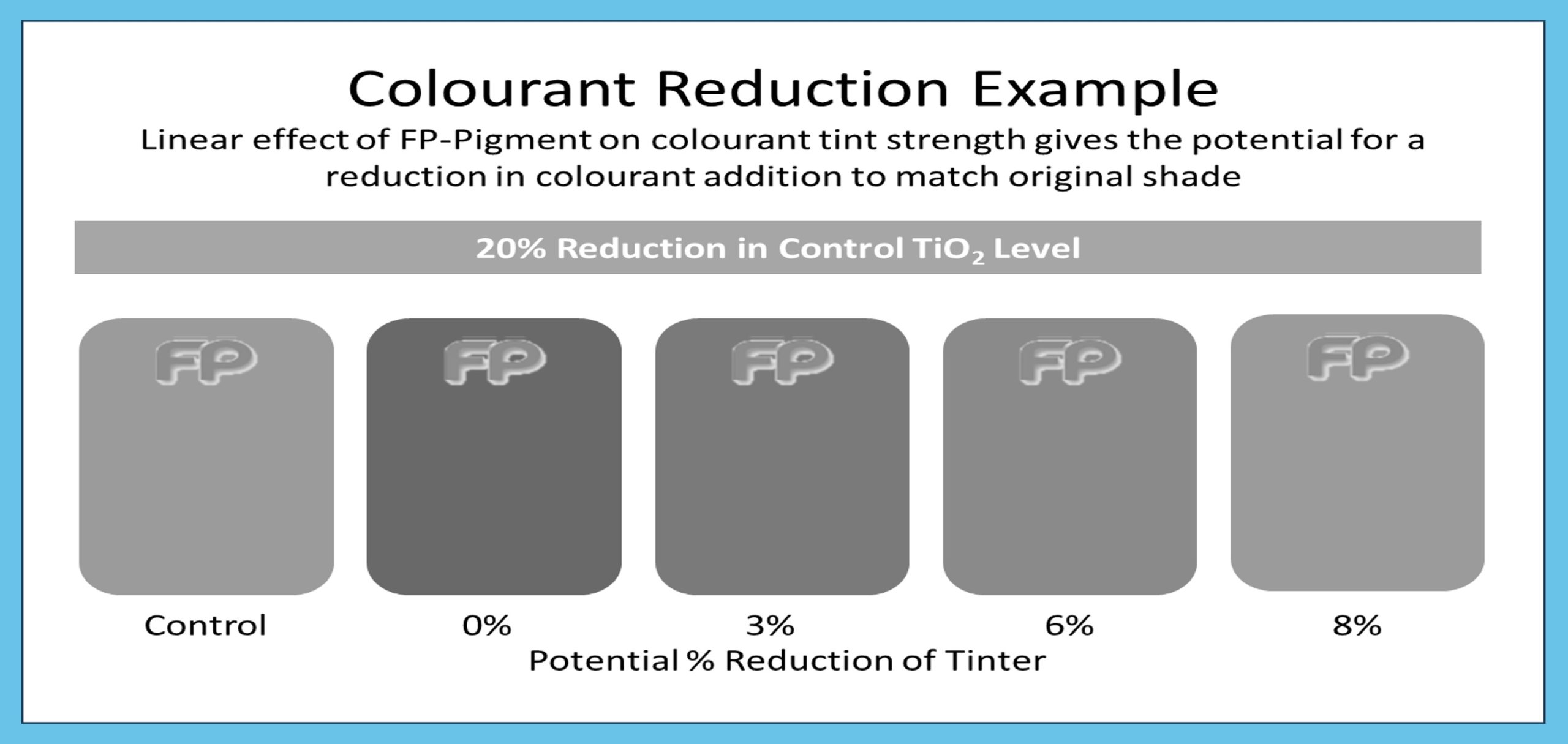

The darker colour obtained when using more than 6% FP-Opacity Pigment™ provides an opportunity for formulators to reduce colourant levels in addition to the reduction in TiO2 pigment.

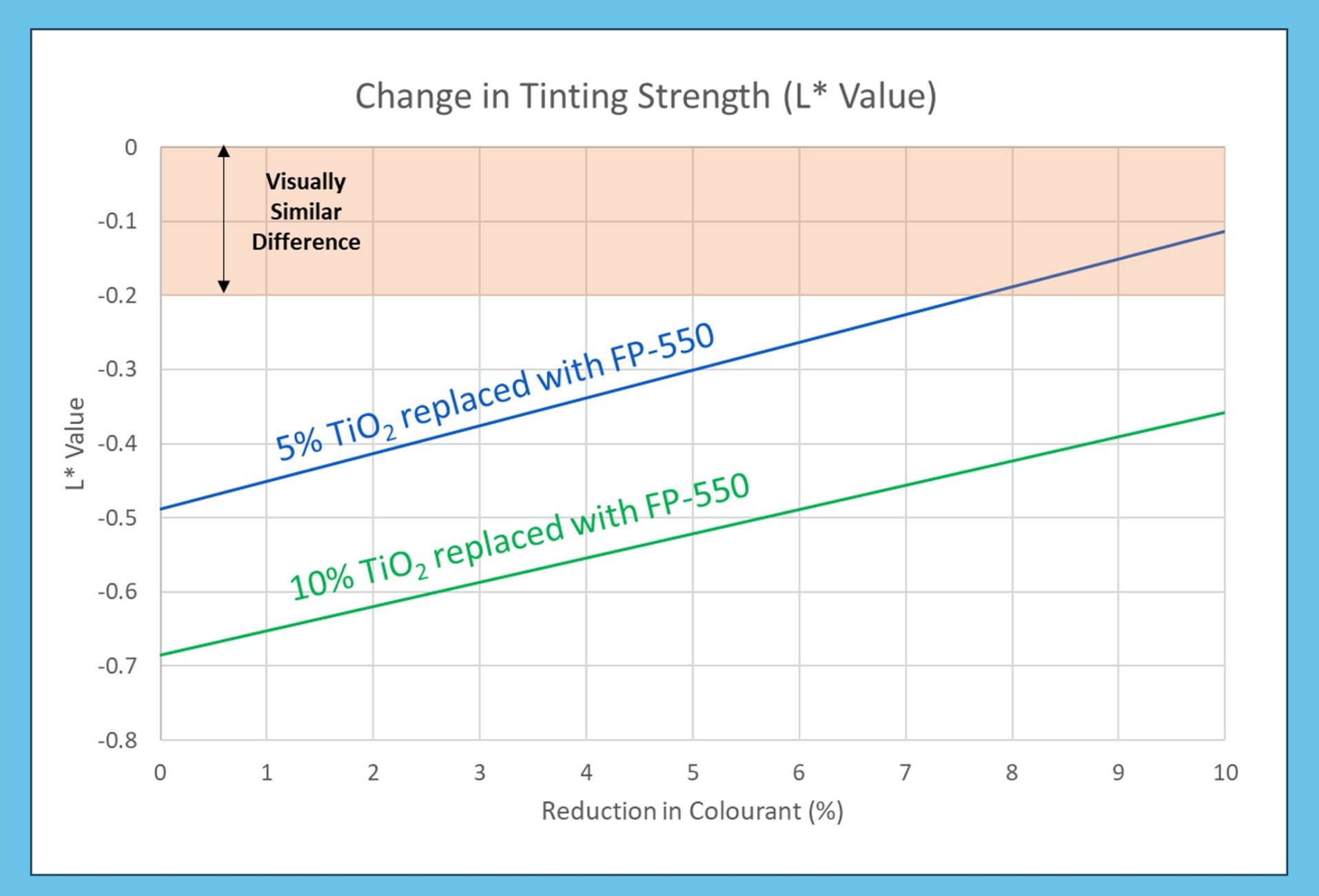

Change in Strength with Colourant Reduction

Under normal circumstances, the partial replacement of TiO2 with FP-Opacity Pigment™ will lead to a reduction in colour strength (lower L* value). The development of a darker colour allows the formulator to reduce the amount of colourant used. A simple series of experiments, lowering the level of coloured pigment added, can be made to identify the correct amount needed to match the original colour (L* value). Once the brightness is matched the Chroma and Hue should be similar to the original product, although in some cases a small change in Hue may require the use of alternative colours.

Example for Organic Yellow Colourant Reduction (PY83)

In the example opposite, two TiO2 replacement levels were selected, 5% and 10%. In both cases, after the initial TiO2 replacement the tint reducing power had fallen resulting in a lower L* Value (darker colours). To achieve a colour match, the colourant level was incrementally reduced until the L* value was within the required specification (typically a ΔL* of ±0.2, but often a ΔE of <0.7). As can be seen in the chart opposite, with a 5% replacement of TiO2 with FP-Opacity Pigment™, the colourant (Organic Yellow PY83) can be reduced by between 8 and 10% in order to achieve a colour match with the original product.

With the 10% TiO2 replacement, a reduction in colourant of 10% was still darker than the original product (ΔL* -0.35). In this case, it may be possible to reduce the colourant further in order to obtain a brightness match, however, care should be taken that the colour (Hue) itself is not significantly changing with higher reduction levels.

Please note: PY85 is a transparent yellow pigment and requires higher levels of TiO2 for opacity. In general, the possible reduction level of a specific colourant will depend on the degree of opacity it imparts; more opaque colours (typically inorganic) may show lower potential replacement levels (both of the TiO2 and of the colourant itself). Overall, the typical colourant reduction level would normally be between 0.5 and 10%.

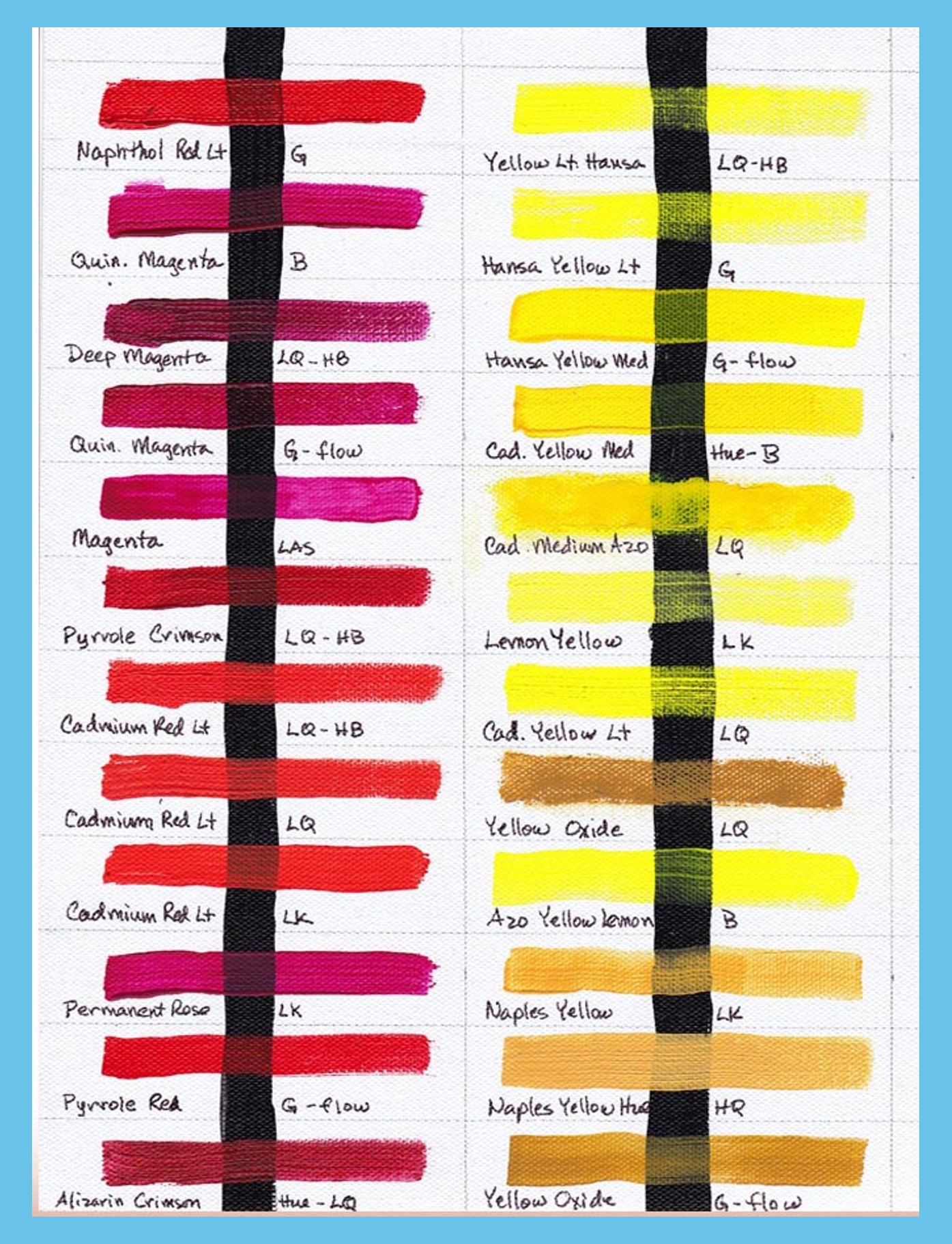

Examples of Colour Pigment Opacity. Image from

Carol A McIntyre

https://www.carolamcintyre.com/

https://www.celebratingcolor.com/color-transparency-and-opacity/

Factors Influence Colour and Opacity

There are many different chemistries for providing colour in Masterbatch. Science is still evolving and yet some excellent chemicals are now deemed too toxic to use. Different adsorbing chemicals also have different refractive indices, particle sizes and will hence all have very different opacifying powers. Choice of pigment relating to cost, sustainability and toxicity also limits the scope of the formulator. However, with the exception of deliberately transparent coatings, all coatings need to be designed to obliterate the substrate at the desired film thickness for the desired application.

In general, the required opacity in a coloured masterbatch is achieved by adding appropriate amounts of TiO2 depending upon the colourant pigment(s) used.